By: Admin / September 5, 2025

By: Admin / September 5, 2025

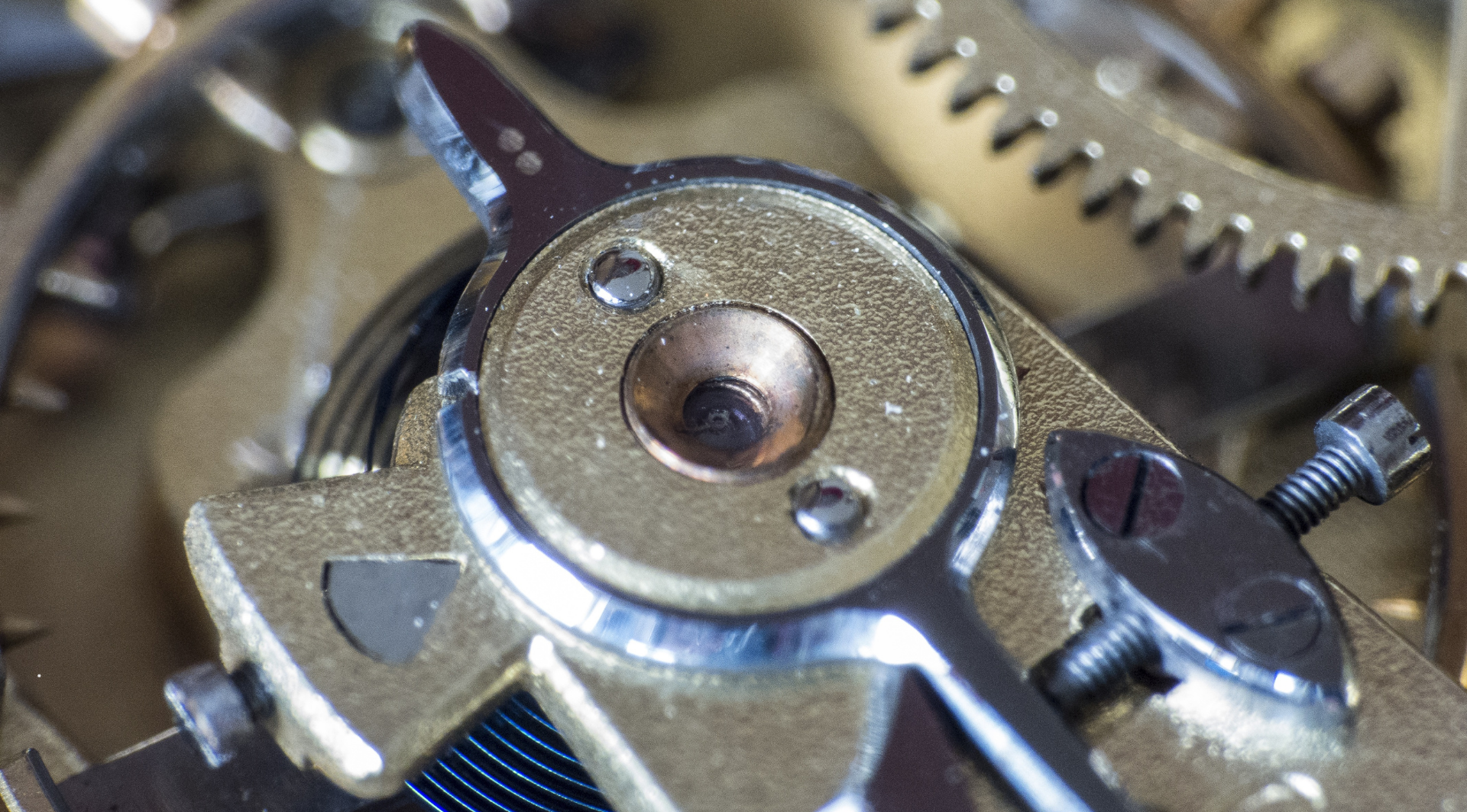

In the field of mechanical engineering and industrial design, gear selection plays a pivotal role in system performance, efficiency, and reliability. Among the most common gear types are spur gears and helical gears, each with distinct advantages, limitations, and industrial applications. While spur gears are renowned for their simplicity and high efficiency, helical gears offer smoother operation and higher load capacity.

For mechanical engineers, quality control managers, and procurement managers, understanding the trade-offs between these two gear types is crucial when designing or sourcing components. This article provides an in-depth, scientific comparison of spur and helical gears, focusing on performance, efficiency, selection criteria, and quality standards.

Spur gears achieve higher efficiency because of their rolling contact. Helical gears, however, introduce axial thrust and sliding friction, which reduces efficiency slightly.

Efficiency Table | Gear Type | Typical Efficiency | Primary Cause of Loss | |———–|——————-|———————–| | Spur Gear | 98–99% | Rolling contact only | | Helical Gear | 95–98% | Sliding + axial thrust |

Helical gears distribute loads across multiple teeth simultaneously, enhancing load capacity and reducing localized stress. Spur gears, by contrast, engage one tooth at a time, leading to higher stress per tooth.

Helical gears typically experience less wear under heavy loads due to smoother meshing, but require robust lubrication systems to manage sliding friction.

The helix angle affects load sharing, efficiency, and axial thrust. Standard ranges are 15°–30°, with higher angles improving smoothness but increasing thrust forces.

Both gear types require carefully controlled backlash. Excessive backlash causes vibration and noise, while insufficient clearance may lead to overheating and premature failure.

Procurement managers should ensure compliance with AGMA quality levels (Q8–Q12 for high-precision applications) or equivalent ISO/DIN standards.

Both gears benefit from carburizing, nitriding, or induction hardening to enhance wear resistance. Alloy steels (4140, 8620, 4340) remain the industry standard.

Tools Used: – CMM (Coordinate Measuring Machine) – Surface hardness testers (Rockwell C) – Magnetic particle inspection for cracks

Advantages: – High efficiency – Cost-effective – Simple design

Limitations: – Noisy at high speeds – Limited load capacity

Advantages: – High load capacity – Quieter operation – Longer life under heavy loads

Limitations: – Axial thrust requires bearings – Slightly lower efficiency – Higher production costs

Choosing between spur and helical gears is not a matter of “better or worse,” but of application-specific requirements. Spur gears remain ideal where efficiency, cost-effectiveness, and simplicity are the priorities. Helical gears excel in high-speed, high-load, and noise-sensitive applications.

For engineers and procurement managers, the right decision depends on project specifications, noise tolerance, and load demands. Ensuring compliance with AGMA, ISO, or DIN standards is critical to guarantee long-term reliability.

👉 Looking for an industrial gears supplier that delivers both spur and helical gears with strict quality standards? Contact MASGearTech today for tailored solutions and a competitive quote.

Leave a Comment